Product Details

Product Details

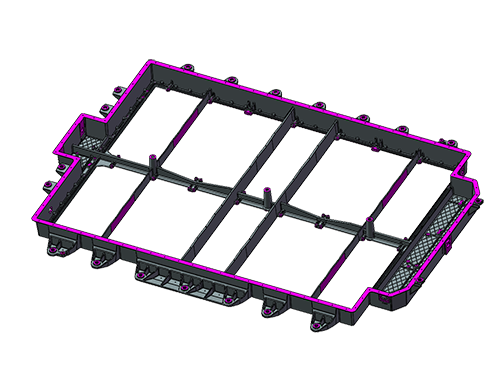

Solution

Battery case Battery tray

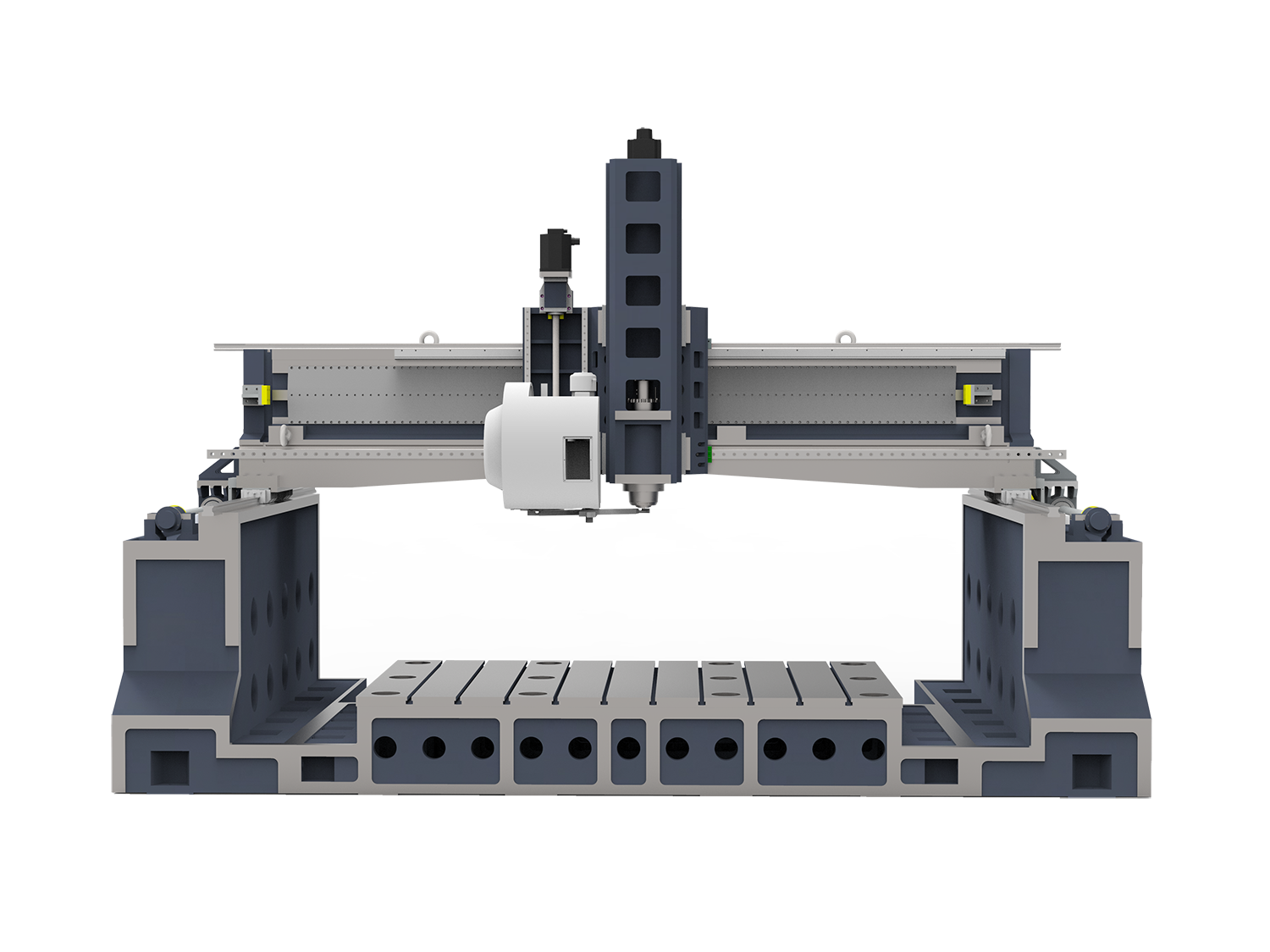

| Model | Unit | TB3017 | TB3027 |

| Stroke | |||

| X-axis stroke | mm | 3000 | |

| Y-axis stroke | mm | 1700 | 2700 |

| Z-axis stroke | mm | 750 | |

| Distance from spindle nose to workbench | mm | 180-930 | |

| Distance between double columns | mm | 4100 | |

| Workbench | |||

| Workbench area | mm | 2800x1800 | 2800x2800 |

| Number of T-slots (width x quantity x spacing) | mm | 22x10x250 | 22x10x250 |

| Workbench load capacity | kg/m2 | 5000 | |

| Spindle | |||

| Spindle rated power | kw | 15/18.5 | |

| Spindle speed | rpm | 10000 | |

| Spindle taper hole | - | BBT40 | |

| Spindle output torque (S1) | N.m | 71.6 | |

| Feed | |||

| Cutting feed speed | m/min | 20000 | |

| Rapid feed speed | m/min | 48000 | |

| Accuracy | |||

| Positioning accuracy | mm | 0.008/300 | |

| Repeat positioning accuracy | mm | 0.005/300 | |

| Automatic tool change | |||

| Tool magazine capacity | PCS | 24 | |

| Maximum tool diameter - adjacent tool | mm | BBT40:Φ75 | |

| Maximum tool diameter - empty adjacent tool | mm | BBT40:Φ120 | |

| Maximum tool length | mm | 200 | |

| Maximum tool weight | kg | BBT40:8 | |

| Others | |||

| Power requirements | - | AC380, 50HZ, 75KVA | |

| Air source pressure | Mpa | 0.5-0.7 | |

| Net weight of the machine | kg | 20000 | 25000 |

| Footprint | mm2 | 5500X5500 | 5500X6500 |

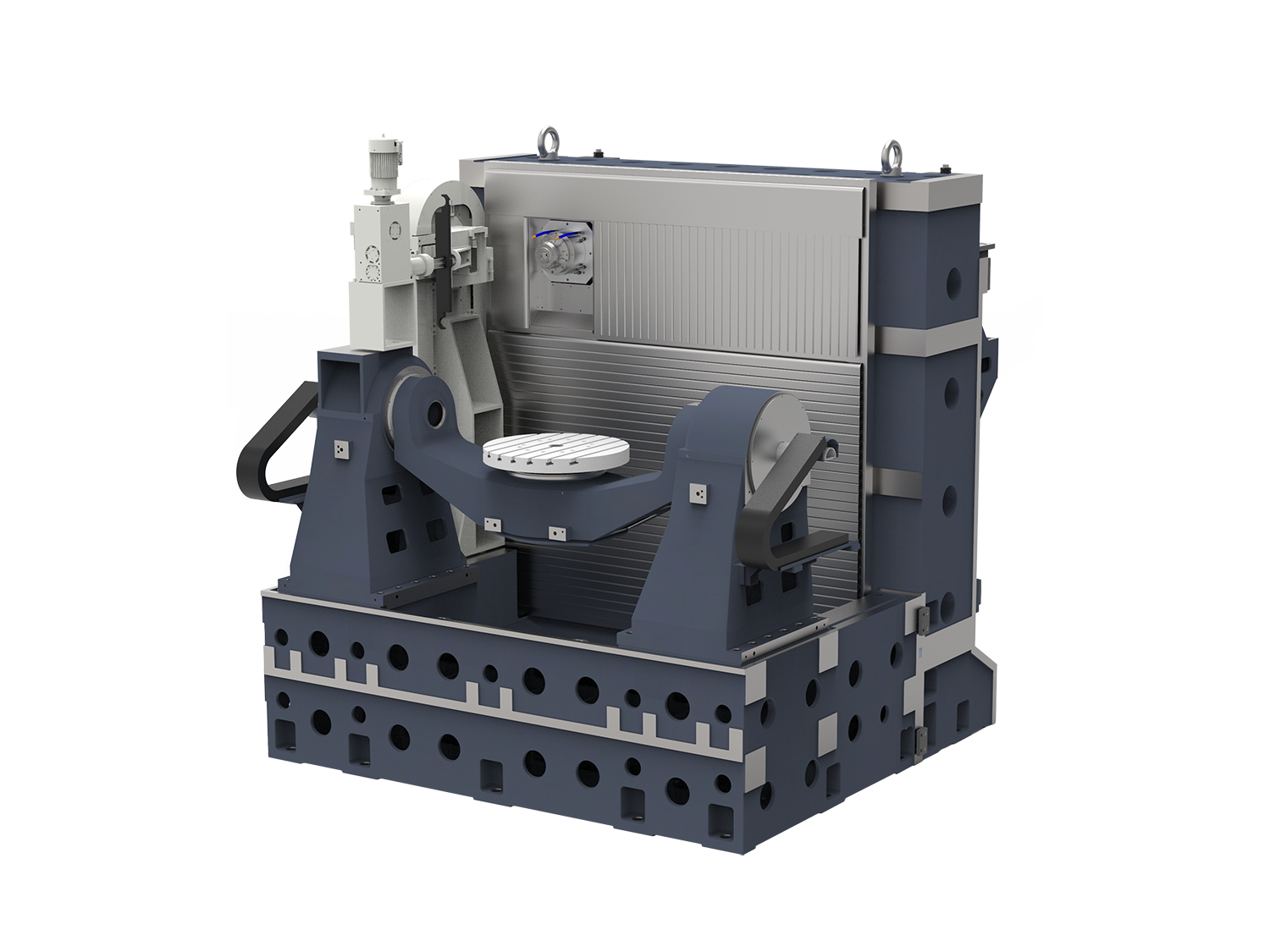

| Standard accessories | Optional accessories | ||

| Huazhong CNC HNC S848 Di | 24T disc tool magazine | SIEMENS 840D SL controller | |

| Single-axis swing head | Double spiral chip conveyor | Spindle center water output 20bar/60bar | |

| Automatic power-off function | Chain plate chip conveyor | Cutting fluid oil-water separation device | |

| Spindle taper hole cleaning air blowing | Left and right moving dynamic operation box | Cutting fluid rain mist cooling device | |

| Spindle cooling system | Electrical box air conditioning | Automatic tool measurement device | |

| X-axis dual grating scale, YZ-axis grating scale | Three-color warning light | Automatic workpiece measurement device | |

| Three-axis stroke hardware limit | Work light | Special requirements software for workpiece measurement | |

| X-axis linear motor, Y-axis dual screw drive, Z-axis single screw drive | Operation handwheel | Transformer | |

| Centralized automatic lubrication device | Foundation leveling adjustment block and umbrella hook | Stabilizer | |

| Cleaning water gun/air gun on the operation side | Toolbox and tools | ||

| Full enclosure protective cover | |||

* Products are continuously updated, product parameters are subject to actual shipment

Previous article

Next article

Previous article

Next article

Recommend products