Product Details

Vertical Milling and Turning Composite Processing Center

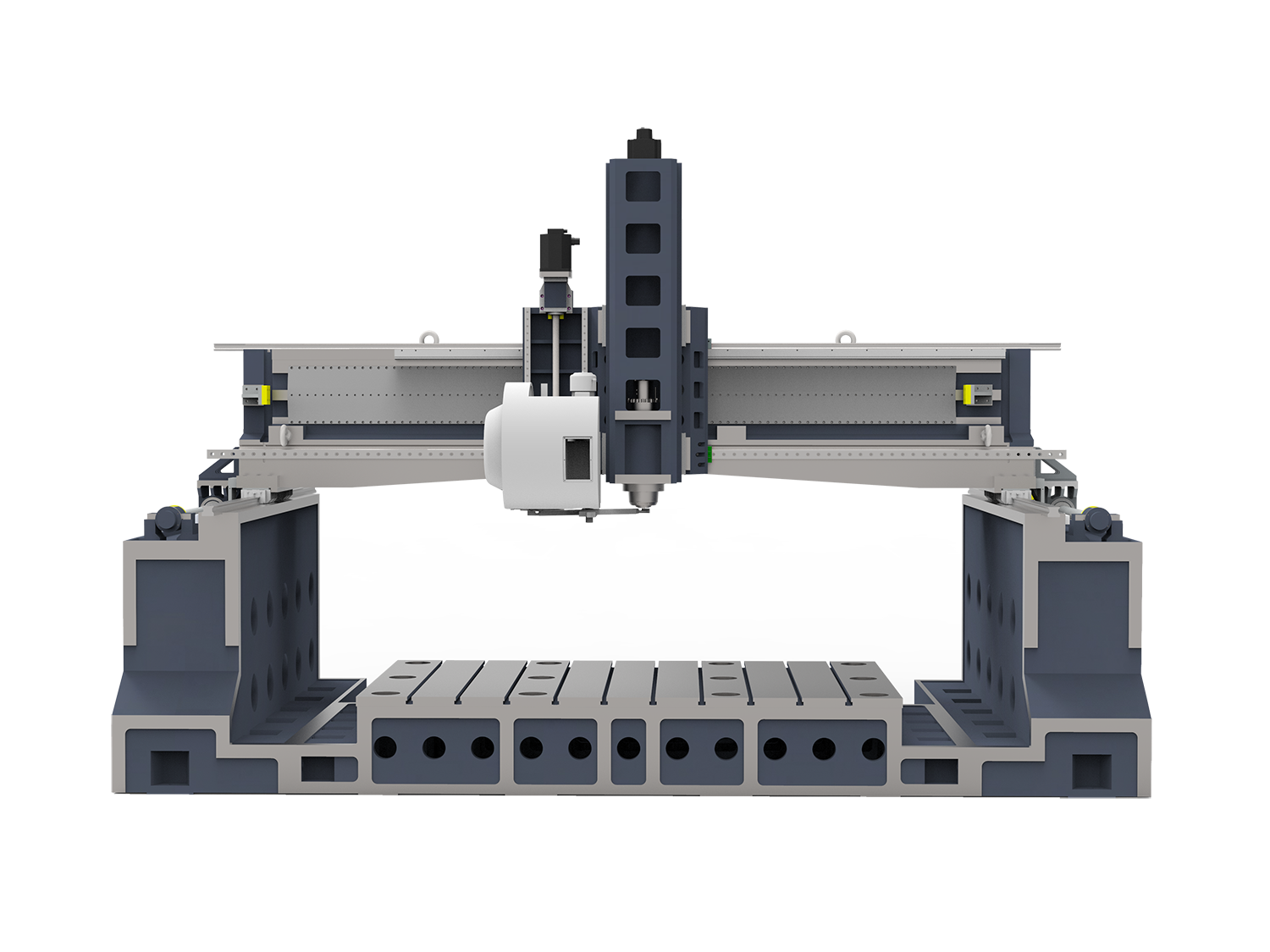

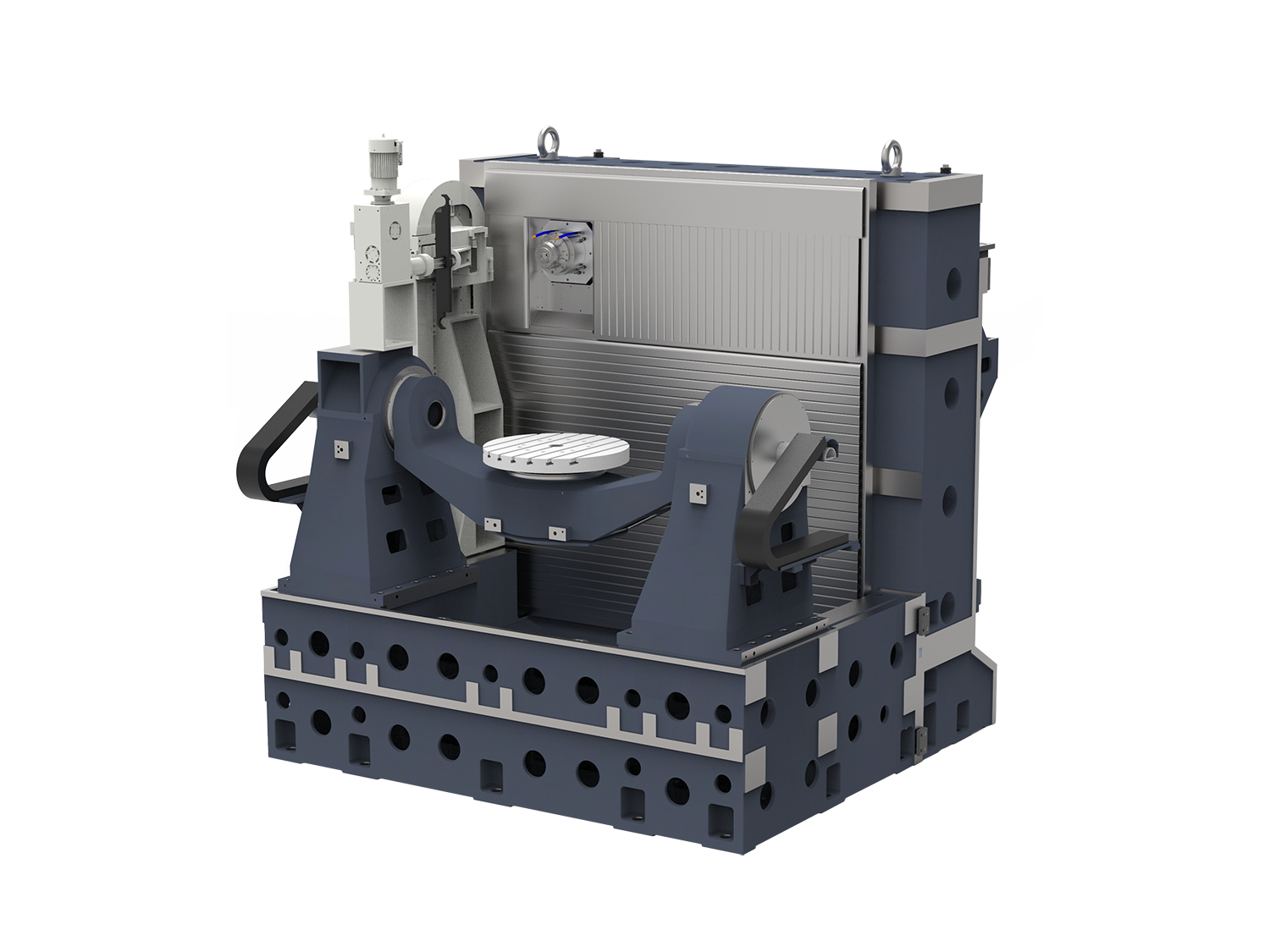

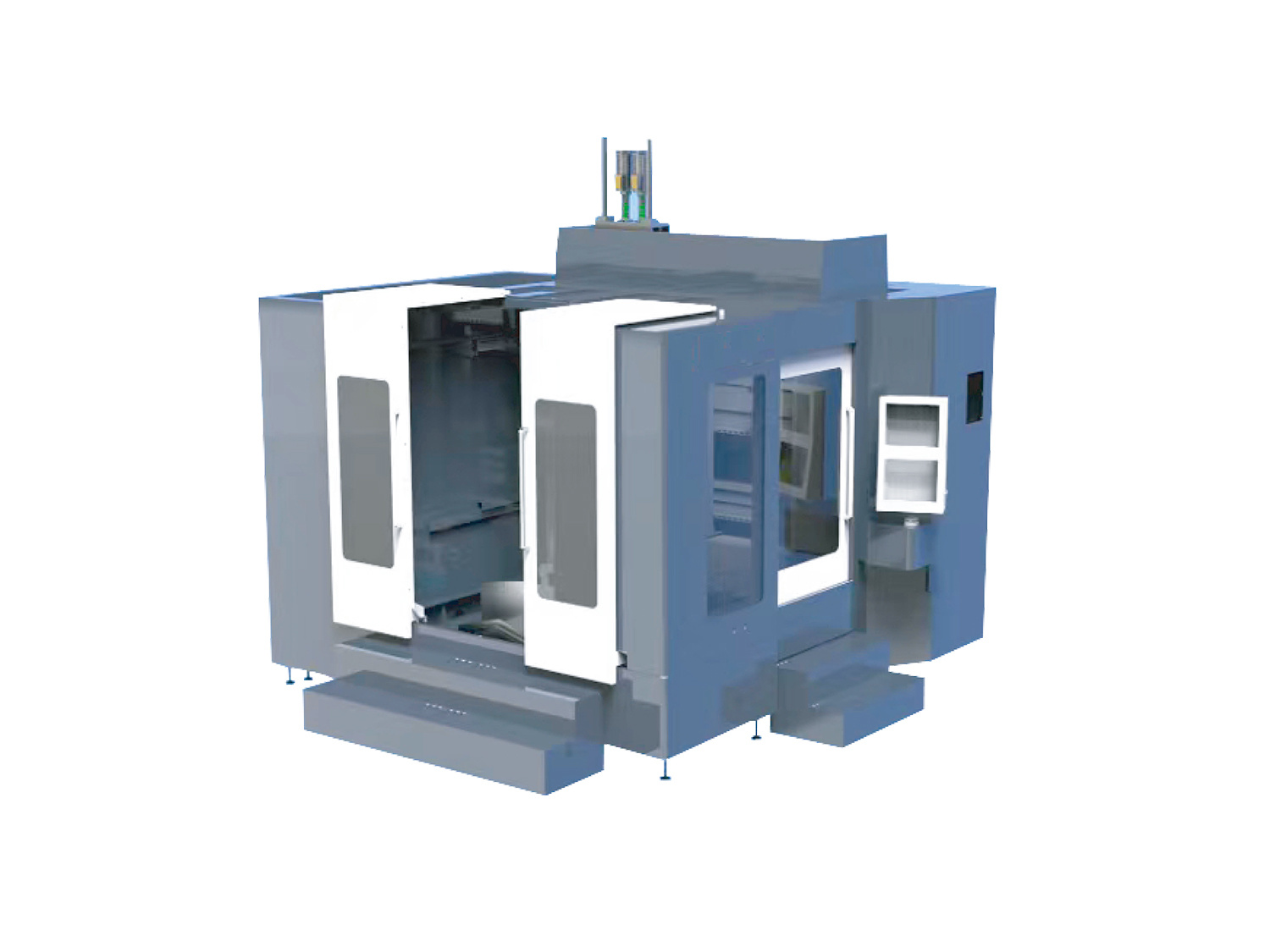

The vertical milling and turning composite processing center adopts a new dynamic column structure with reliable milling performance.

Key Words

Goldsmiths Smart, Equipment, Professional

Classification

New Energy Vehicle Series

Product Details

Solution

Motor housing cover

Mechanical characteristics

1. Three-axis heavy-duty roller guide, high rigidity.

2. Brand new moving column structure, reliable milling performance.

3. Integrated turning and milling spindle, unparalleled high productivity.

4. Large Z-axis travel, covering a wider processing range.

| Model | Unit | TMC400/A |

| Travel | ||

| X-axis travel | mm | 650 |

| Y-axis travel | mm | 450 |

| Z-axis travel | mm | 650 |

| Distance from spindle nose to table (vertical) | mm | 150-800 |

| Minimum division of C-axis | ° | 0.001° |

| C-axis swing angle | ° | nx360° |

| Table | ||

| Table area | mm | Φ400/12H7 |

| Table load | mm | 200 |

| Spindle | ||

| Rated power of spindle | kw | 11 |

| Spindle speed | rpm | HSK T63/BBT40 |

| Spindle taper hole | - | 8000 |

| Spindle output torque (S1/S6) | N.m | 52.5/118 |

| Feed | ||

| Cutting feed speed | m/min | 10000 |

| Rapid feed speed | m/min | 20000 |

| Accuracy | ||

| Positioning accuracy | mm | 0.008/300 |

| Repeat positioning accuracy | mm | 0.005/300 |

| Automatic tool change | ||

| Tool magazine capacity | PCS | 24T/30T/40T |

| Maximum tool diameter - adjacent tool | mm | Φ80 |

| Maximum tool diameter - adjacent empty tool | mm | Φ150 |

| Maximum tool length | mm | 300 |

| Maximum tool weight | mm | 8 |

| Others | ||

| Power requirements | - | AC380, 50HZ, 50KVA |

| Air source pressure | Mpa | 0.5-0.7 |

| Net weight of machine | kg | Approximately 6200 |

| Footprint | mm2 | 4200X3050 |

| Standard accessories | Optional accessories | ||

| Huazhong CNC 828 DI controller | Electrical box air conditioning | New generation | |

| Automatic power-off function | Three-color warning light | Spindle center water outlet 20bar/60bar | |

| Spindle taper hole cleaning air blow | Work light | Cutting fluid oil-water separation device | |

| Spindle cooling system | Operation handwheel | Cutting fluid rain mist cooling device | |

| Spindle annular cutting fluid cooling system | Foundation leveling adjustment block and umbrella hook | Automatic workpiece measurement device | |

| Centralized automatic lubrication device | Toolbox and tools | Special requirements software for workpiece measurement | |

| Full enclosure outer protective cover | Milling and turning composite processing function (full series) | Transformer | |

| 24T disc tool magazine | Stabilizer | ||

* Products are continuously updated, product parameters are subject to actual shipment

Previous article

Next article

Previous article

Next article

Recommend products