Product Details

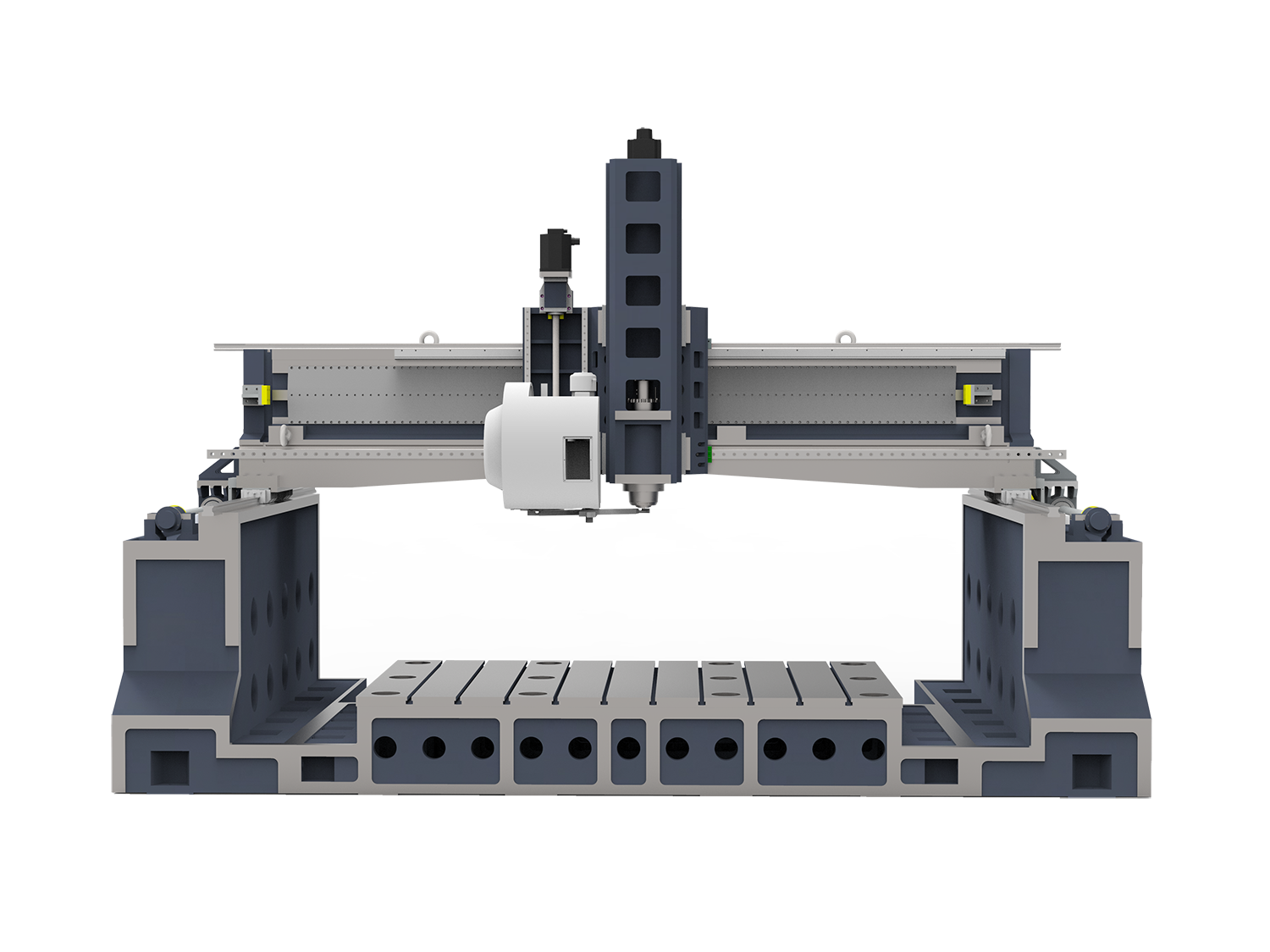

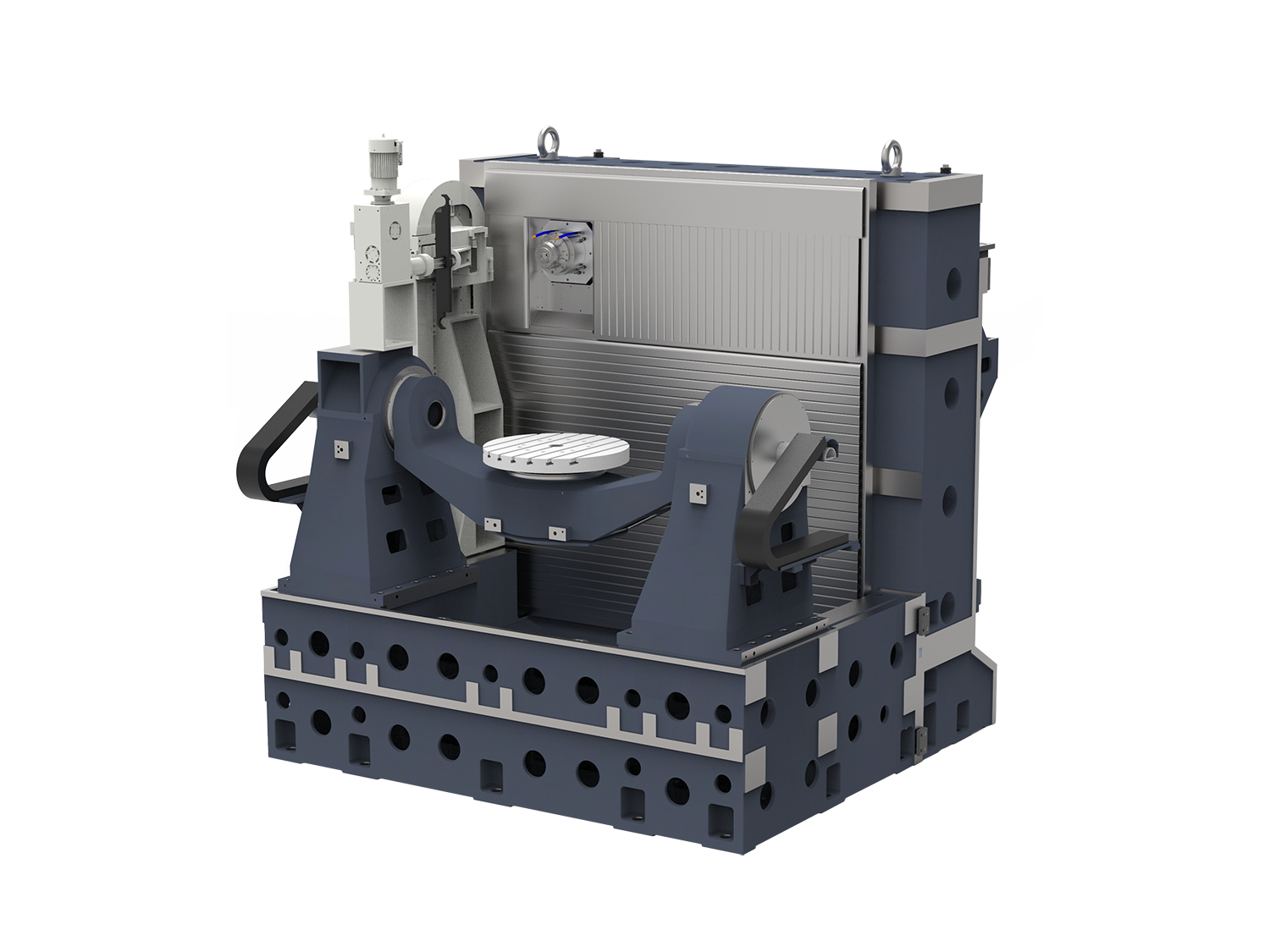

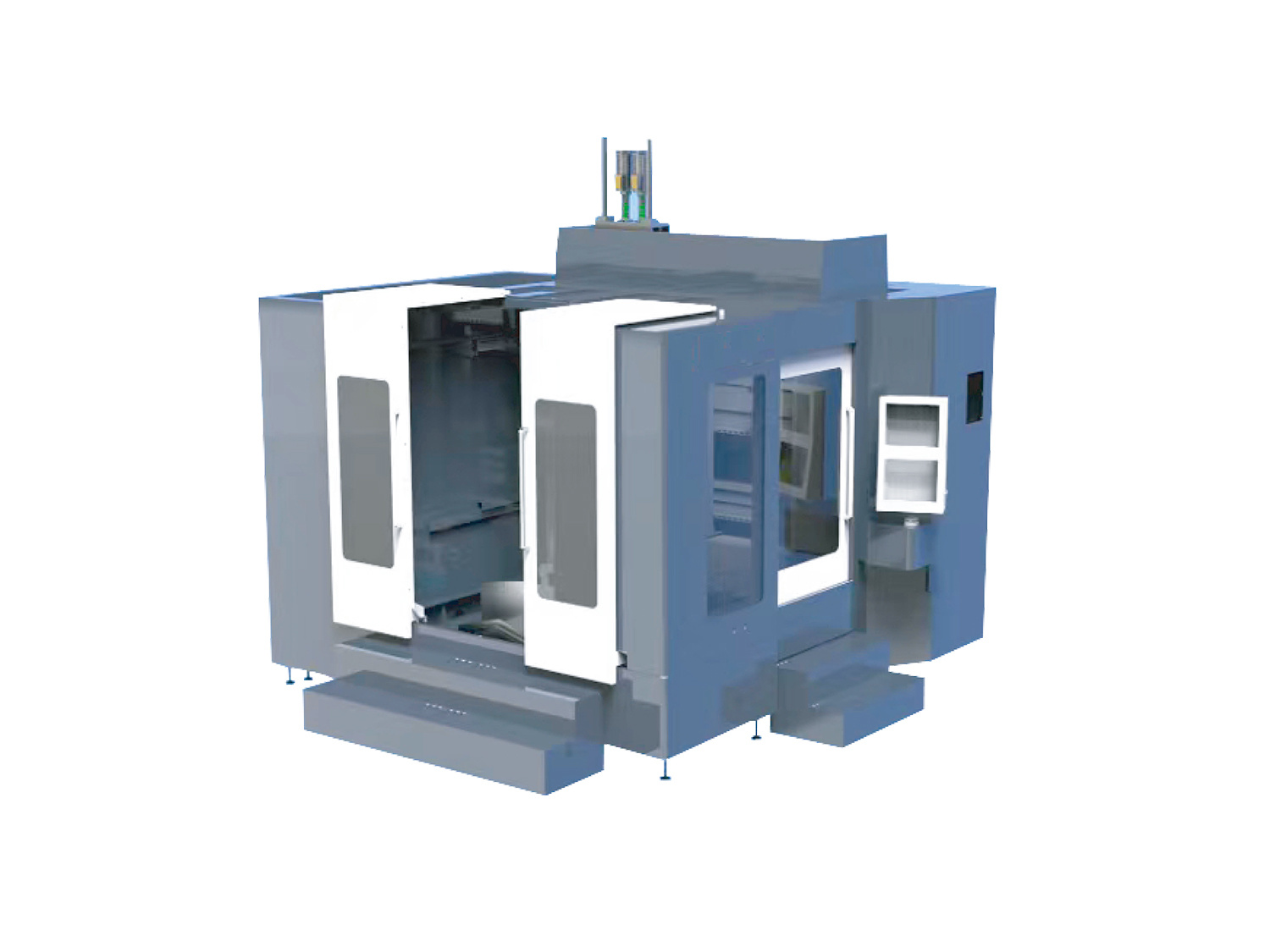

Vertical and horizontal composite machining center

Key Words

Goldsmiths Smart, Equipment, Professional

Classification

New Energy Vehicle Series

Product Details

Mechanical Characteristics

1. The machine tool adopts an L-shaped structure, with the base and column cast from a mineral casting formula sourced from Switzerland, which has no internal stress and does not require aging to relieve stress, ensuring good static precision stability of the machine tool. Mineral castings have excellent shock absorption properties, and the material itself can absorb vibrations generated during processing, thus ensuring good dynamic performance of the machine tool. The thermal conductivity of the mineral casting material is one-fiftieth that of cast iron, ensuring long-term thermal stability of the machine tool.

2. Moving components are made of HT300 cast iron to ensure the rigidity of the machine tool.

3. The C-axis uses a DD direct drive five-axis cradle, equipped with a 5 arc-second circular grating and a Festo rotor.

4. The B-axis uses a DD torque motor swing head, equipped with a 5 arc-second circular grating and a Festo rotor.

| Mechanical Parameters | Unit | LW1060 | LW1280 | LP1250 | LW1612 |

| Table Surface Size | mm | Ф630/18H7 | Ф800/14H7 | Ф1250/18H7 | Ф1000/18H7 |

| Table Load Capacity | kg/m2 | 500 | 1000 | 2000 | 1000 |

| Three-axis Stroke | mm | 1000X900X600 | 1200X1000X1000 | 1850X2000X1000 | 1600X1000X1200 |

| A-axis Swing Angle (Minimum Division 0.001°) | Degrees | 0~180° | -20~120° | -20~120° | -20~120° |

| C-axis Swing Angle | Degrees | nx360° | nx360° | nx360° | nx360° |

| Distance from Spindle End Face to Table Surface | mm | 100-450 | 150-500 | 100-650 | 100-750 |

| Spindle Taper | HSK A63/BBT40 | HSK A63/BBT40 | HSK A63/BBT40 | HSK A63/HSK A100 | |

| Spindle Type | Electric Spindle | Electric Spindle | Electric Spindle | Electric Spindle | |

| Spindle Rated Power | kw | 30 | 30 | 54 | 30/54 |

| Spindle Maximum Speed | rpm | 18000 | 18000 | 10000 | 18000/10000 |

| Spindle Torque (S1/S6) | NM | 72/85 | 72/85 | 200/240 | 75/150, 260/300 |

| Spindle Diameter (mm) | mm | Ф190 | Ф190 | Ф230 | Ф190/230 |

| Maximum Tool Diameter | mm | Ф75/140 | Ф75/140 | Ф75/140 | Ф75/140 |

| Tool Magazine | 32T | 32T/40T | 32T/40T | 32T/40T | |

| Maximum Tool Length | mm | 200 | 300 | 300 | 300 |

| Maximum Tool Weight | kg | 4 | 8 | 15 | 8/15 |

| Tool Change Time | sec | 8 | 8 | 8 | 8 |

| Three-axis Rapid Movement Speed | mm/min | 36000 | 36000 | 36000 | 36000 |

| X.Y.Z Axis Motor Connection Method | Direct Connection | Direct Connection | Direct Connection | Direct Connection | |

| X.Y.Z Axis Motor Torque | NM | 36/36/36 | 36/36/36 | 55/55/55 | 55/55/55 |

| A.C Axis Motor Torque | NM | 1800/1000 | 800/2000 | 1000/3000 | 6000/3000 |

| A.C Axis Maximum Speed | rpm | 20/300 | 60/100 | 60/100 | 60/100 |

| Compensated X.Y.Z Positioning Accuracy | mm | ≤0.005 | ≤0.005 | ≤0.006 | ≤0.008 |

| Compensated X.Y.Z Repeated Positioning Accuracy | mm | ≤0.003 | ≤0.003 | ≤0.004 | ≤0.008 |

| Positioning Accuracy | s | ≤5 | ≤6 | ≤8 | ≤10 |

| Repeated Positioning Accuracy | s | ≤3 | ≤3 | ≤5 | ≤5 |

| Controller | Siemens S840D | ||||

| Air Pressure Specification | kg/mm² | 0.5-0.7 | |||

| Footprint | mm | / | / | / | / |

| Machine Weight | kg | Approximately 11000 | Approximately 18000 | Approximately 30000 | Approximately 20000 |

| Standard Accessories | Optional Accessories | ||

| Air Gun | Tool Locking Device | Water Gun | Milling and Turning Composite |

| ER Tool Holder | Chain Plate Chip Conveyor | Contact Tool Setting Instrument | Online Measurement |

| Explosion-proof Work Light | Water Cooling Machine | Laser Tool Setting Instrument | Central Water Outlet |

| Toolbox (including hex wrench, flat/philips screwdriver) | Heat Exchanger | GSK 25i | |

| Tool Magazine | Siemens S840D | Huazhong 848 | |

* Products are continuously updated, product parameters are subject to actual shipment.

Previous article

Next article

Previous article

Next article

Recommend products