Product Details

Product Details

Product Introduction

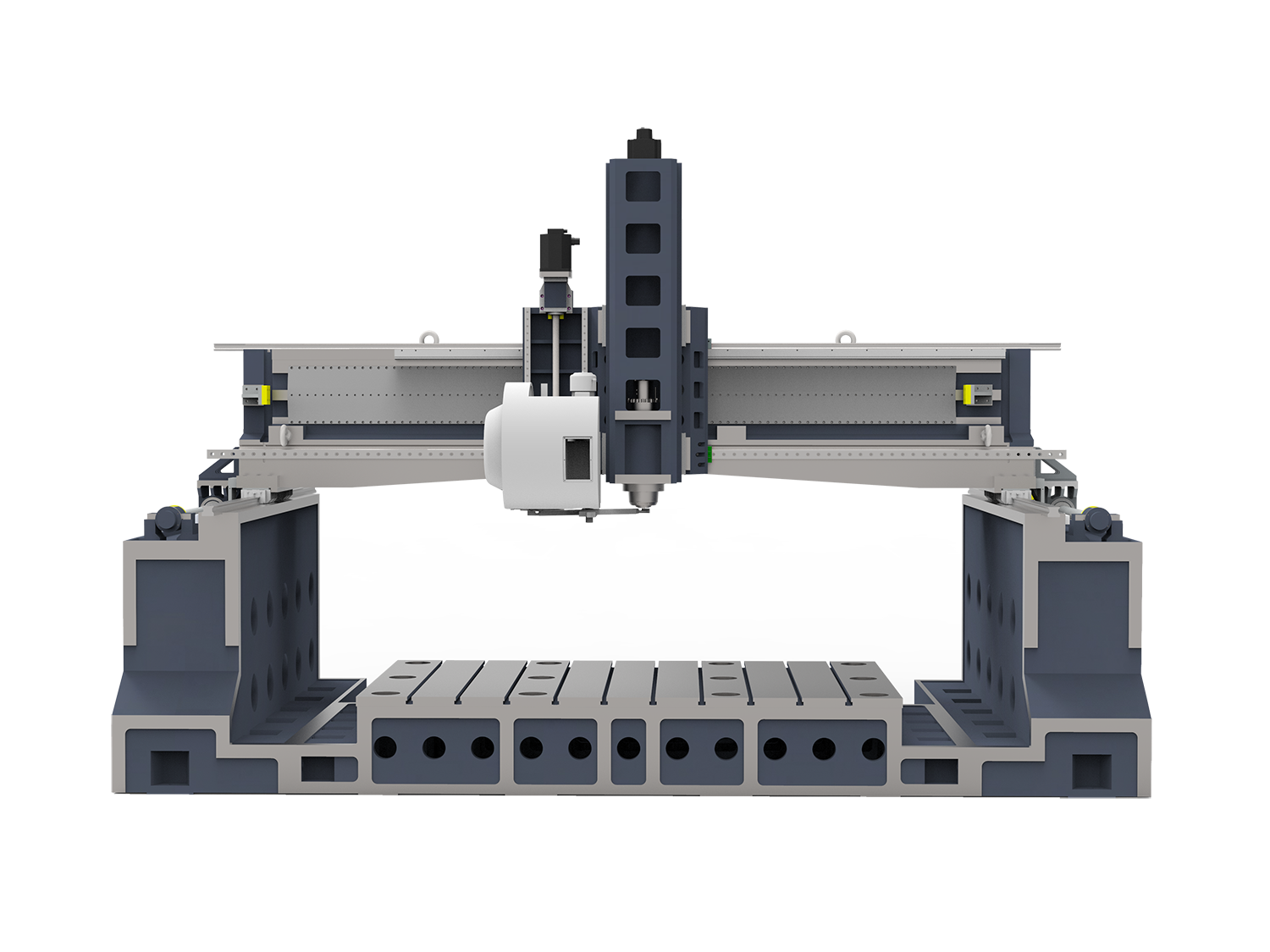

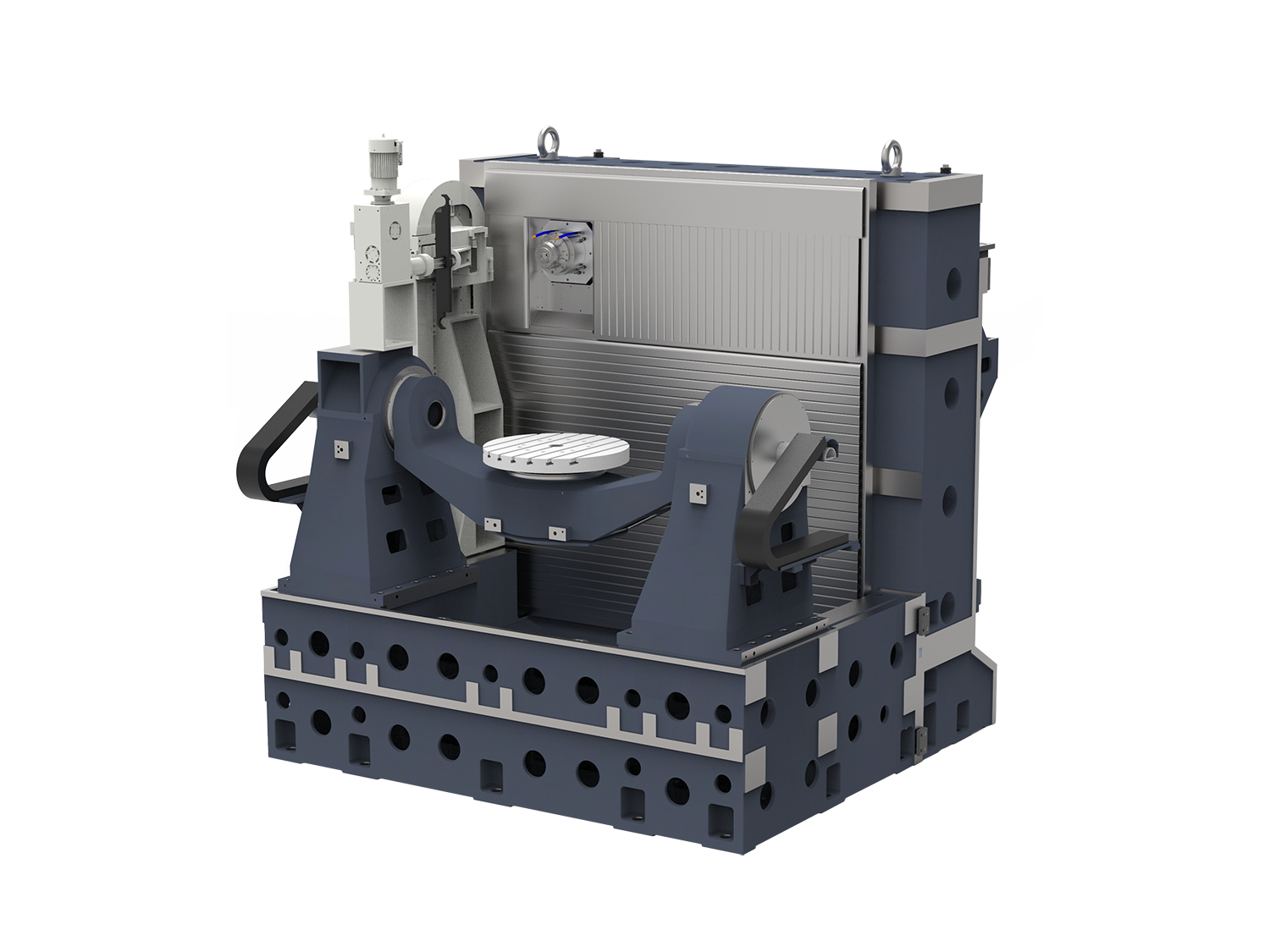

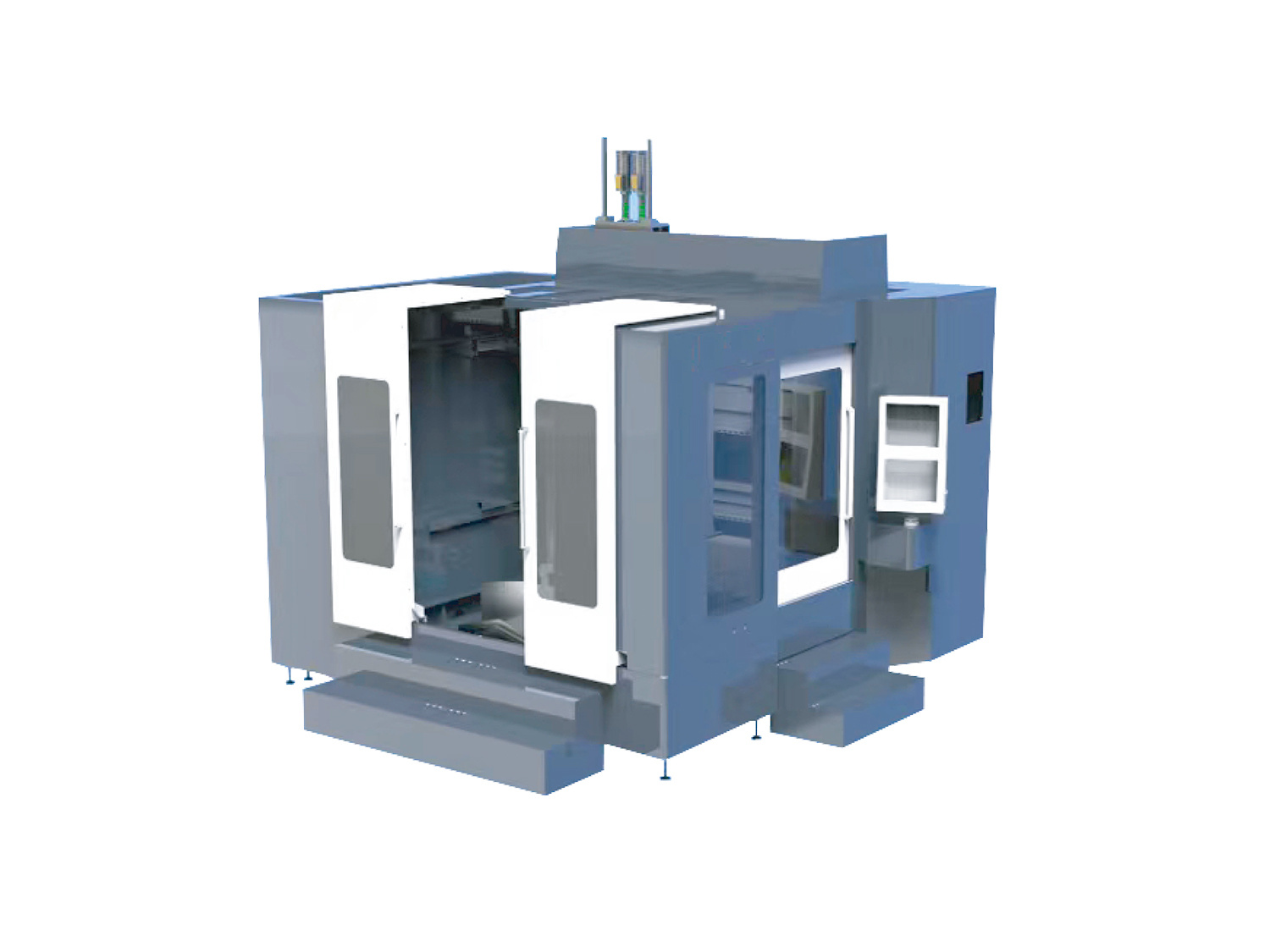

The NV vertical machining center machine is a component processing model specially designed for high speed and high precision. The main structural components are made of high-strength cast iron, and the three-axis is designed with ball and wire tracks to improve the response speed of the servo motor and meet the requirements of high-speed machining.

Mechanical characteristics

1. Three axis fast movement 36m/min.

2. The three-axis adopts high rigidity track support, fast response, and high precision.

3. The classic sheet metal appearance layout is more in line with ergonomic design, with the operating interface and spindle in the most suitable position, ensuring convenient operation of the machine.

4. All lubrication systems use volumetric distributors to ensure uniform oil supply to all lubrication points, ensuring good mechanical lubrication and extending the service life of critical components;

5. The rear chip cleaning method enhances the strength of the chassis chips, and the cleaning machine tool does not need to be stopped.

| Mechanical parameters | Unit | NV644 | NV866 | NV866L | NV1066 | NV1066L |

| Three axis travel (X/Y/Z) | mm | 600X410X450 | 800X600X600 | 800X600X600 | 1000X600X600 | 1000X600X600 |

| Workbench area | mm2 | 700X420 | 1000X600 | 1000X600 | 1100X600 | 1100X600 |

| T-shaped groove | mm | 14X3, span 105 | 18X5,span 110 | 18X5,span 110 | 18X5,span 110 | 18X5,span 110 |

| Workbench load-bearing capacity | kg/m2 | 350 | 600 | 600 | 600 | 600 |

| Distance from spindle center to column | mm | 480 | 650 | 650 | 650 | 650 |

| Distance from spindle nose to worktable | mm | 110-560 | 80-680 | 380-980 | 80-680 | 380-980 |

| Three axis motor power | kw | 2/2/3 | 2/2/3 | 2/2/3 | 2/2/3 | 2/2/3 |

| Three axis guide rail | Ball linear guide | Ball linear guide | Ball linear guide | Ball linear guide | Ball linear guide | |

| Three-axis screw | mm | Lead 12 | Lead 12 | Lead 12 | Lead 12 | Lead 12 |

| Three axis rapid feed | m/min | 36 | 36 | 36 | 36 | 36 |

| Specification of spindle end | Directly connected BT40-120 | Directly connected BT40-140 | Directly connected BT40-140 | Directly connected BT40-140 | Directly connected BT40-140 | |

| Spindle speed | rpm | 15000 | 12000 | 12000 | 12000 | 12000 |

| Spindle motor power | kw | 5.5/7.5 | 7.5/11 | 7.5/11 | 7.5/11 | 7.5/11 |

| positioning accuracy | mm | 0.005/300 | ||||

| Repetitive positioning accuracy | mm | 0.003/300 | ||||

| Controller | MITSUBISHI: M80B | |||||

| Air compression specifications | Mpa | 0.5-0.7 | ||||

| Power Supply | AC380V;50Hz;About 15KVA | AC380V;50Hz;About 20KVA | ||||

| External dimensions | mm | 1730X2400X2500 | 2540X3050X2800 | 2540X3050X3100 | 2950X3050X2800 | 2950X3050X2800 |

| Mechanical weight | kg | About 4000 | About 4500 | About 5000 | About 4800 | About 5200 |

| Standard accessories | Optional accessories | ||

| Air gun/water gun | Chassis flushing | hinge type | spiral type |

| ER knife handle | Lock knife holder | Chassis flushing | |

| Explosion proof work light | Spindle oil cooler | Oil water separator | |

| Toolbox (including Allen wrench, Phillips screwdriver) | heat exchanger | Contact type tool setter | |

| 24T disc cutter magazine | MITSUBISHI:M80B | FANUC: 0i-MF Plus (5 packs) | |

*The product is constantly updated, and the product parameters are subject to actual shipment

Previous article

Next article

Previous article

Next article

Recommend products