Product Details

Product Details

Product Introduction

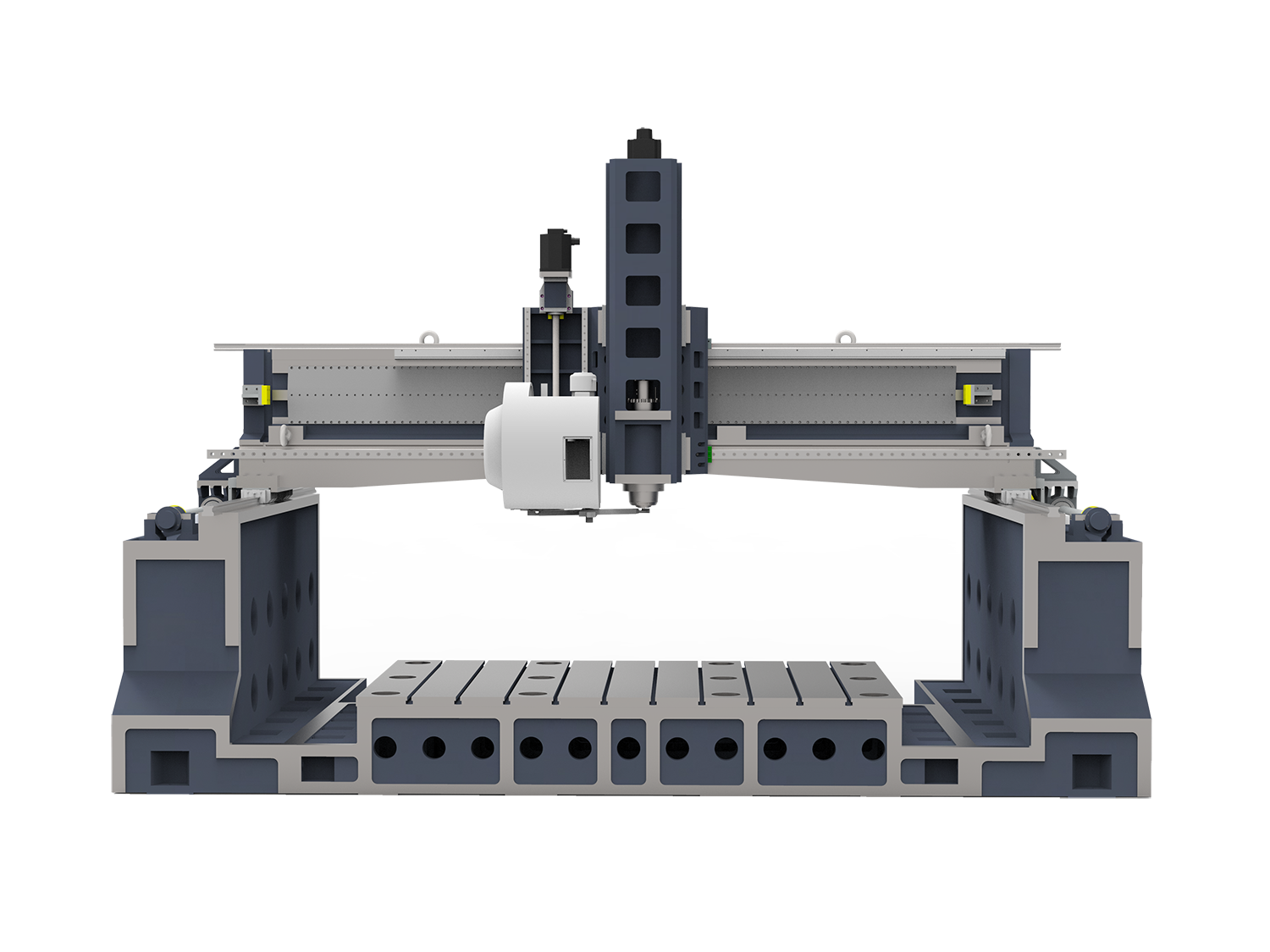

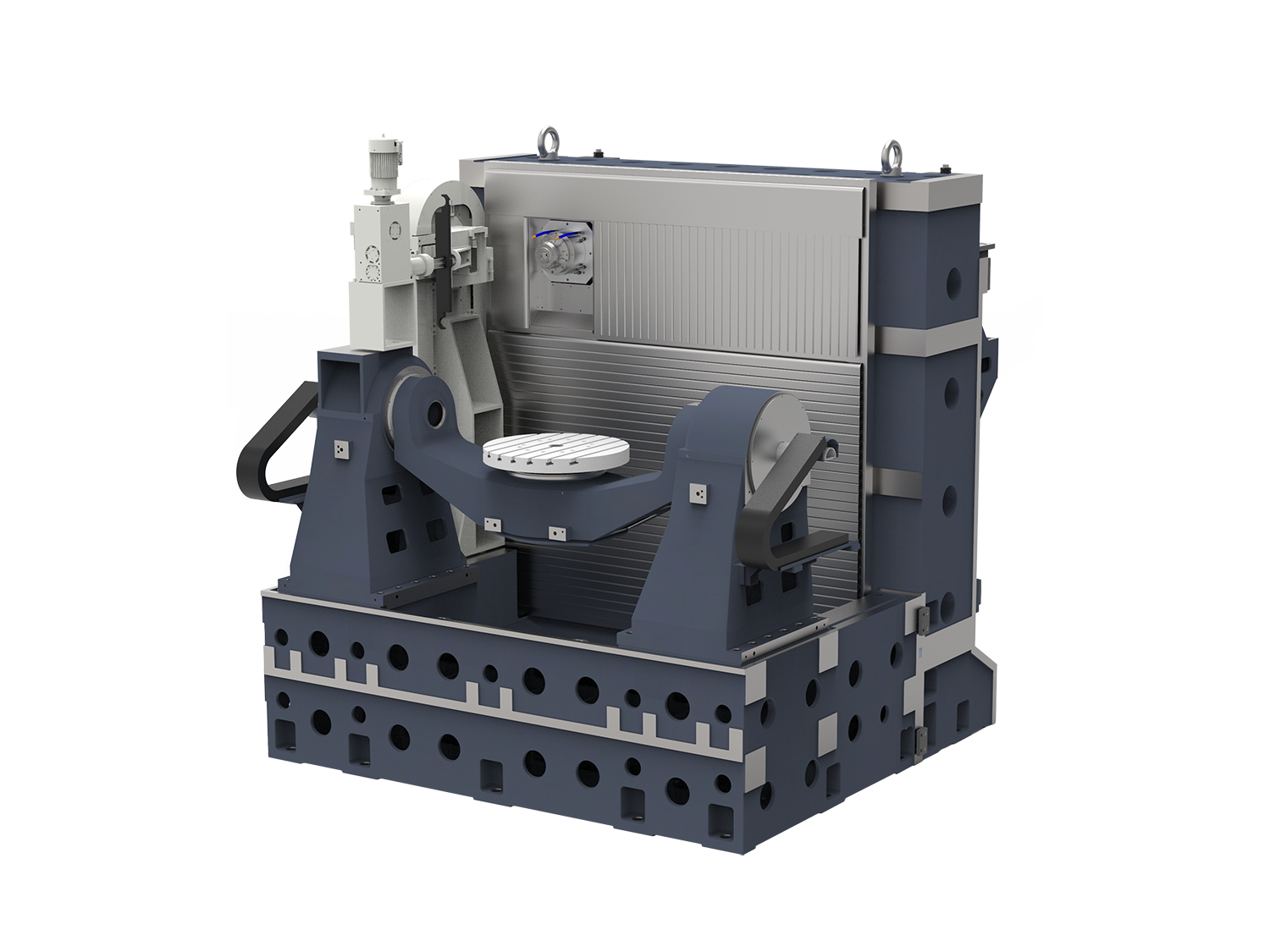

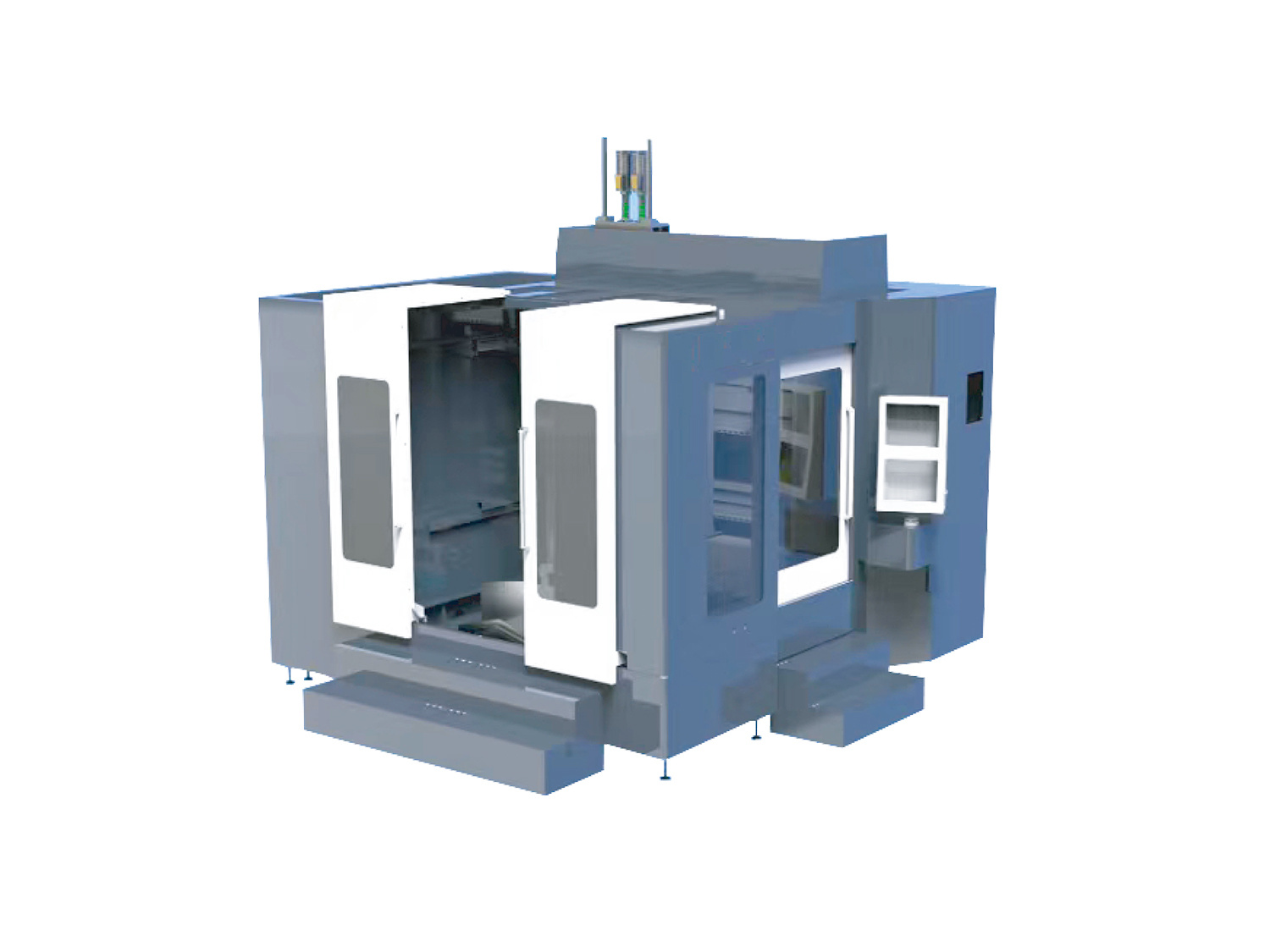

JXV vertical machining center machine is a comprehensive machining model specially designed for high speed and high precision. The main structural components are made of high-strength cast iron, and the three-axis adopts a roller track design. Extended sliding blocks are selected to increase the support surface, improve the load capacity, and meet the requirements of heavy cutting and high-precision machining.

Mechanical characteristics

1. The mechanical mechanism is optimized using finite element analysis software to achieve a good state of mechanical structure.

2. The screw assembly adopts patented design to ensure stable accuracy of the screw.

3. The machine tool base is designed with a bold shape, and the contact area between the foot pad and the ground is increased to ensure the rigidity of the machine tool.

4. The workbench has undergone high-frequency heat treatment, with a hardness of up to HRC50 and better wear resistance.

5. Cast iron undergoes high-temperature tempering and aging treatment to eliminate internal stress in castings and ensure long-term maintenance of mechanical accuracy.

| Mechanical parameters | Unit | JXV855 | JXV1166 | JXV1370 | JXV1580 |

| Three axis travel (X/Y/Z) | mm | 820X570X570 | 1120X620X620 | 1300X700X700 | 1500X800X700 |

| Workbench area | mm2 | 1020X550 | 1220X600 | 1500X700 | 1700X800 |

| T-shaped groove | mm | 18X5, span 90 | 18X5,span 100 | 18X7,span 100 | 18X6,span 125 |

| Workbench load-bearing capacity | kg/m2 | 650 | 950 | 1100 | 1300 |

| Distance from spindle center to column | mm | 600 | 670 | 760 | 850 |

| Distance from spindle nose to worktable | mm | 110-680 | 110-710 | 130-830 | 150-850 |

| Three axis motor power | kw | 3/3/3 | 3/3/3 | 3/3/3 | 3/3/3 |

| Three axis guide rail | Ball linear guide | Ball linear guide | Roller linear guide | Roller linear guide | |

| Three-axis screw | mm | NSK (lead 10) | NSK (lead 10) | Lead 10 | Lead 10 |

| Three axis rapid feed | m/min | 30 | 30 | 24 | 24 |

| Specification of spindle end | Directly connected BBT40-150 | Directly connected BBT40-150 | Directly connected BT50-155 | Belt type BT50-190 | |

| Spindle speed | rpm | 15000/18000 | 15000/18000 | 10000 | 8000 |

| Spindle motor power | kw | 11/15 | 11/15 | 15/18.5 | 18.5/22 |

| positioning accuracy | mm | 0.003/300 | 0.005/300 | ||

| Repetitive positioning accuracy | mm | 0.002/300 | 0.003/300 | ||

| controller | MITSUBISHI:M80A | ||||

| Air compression specifications | Mpa | 0.5-0.7 | |||

| Power Supply | AC380V;50Hz;About 25KVA | AC380V;50Hz;About 30KVA | AC380V;50Hz;About 35KVA | ||

| External dimensions | mm | 2640X2875X2900 | 3160X3020X3000 | 3500X3200X3150 | 3800X3300X3600 |

| Mechanical weight | kg | About 5500 | About 7000 | About 9000 | About 11000 |

| Standard accessories | Optional accessories | ||

| Air gun | Lock knife holder | Water gun | hinge type |

| ER knife handle | 6-inch angle tiger pliers | spiral type | 24T disc cutter magazine |

| Explosion proof work light | Spindle oil cooler | Oil water separator | Chassis flushing |

| Toolbox (including Allen wrench, Phillips screwdriver) | heat exchanger | Z-axis nitrogen balance system | Contact type tool setter |

| MITSUBISHI:M80A | FANUC: 0i-MF Phus (1 pack) | ||

*The product is constantly updated, and the product parameters are subject to actual shipment

Previous article

Next article

Previous article

Next article

Recommend products