Product Details

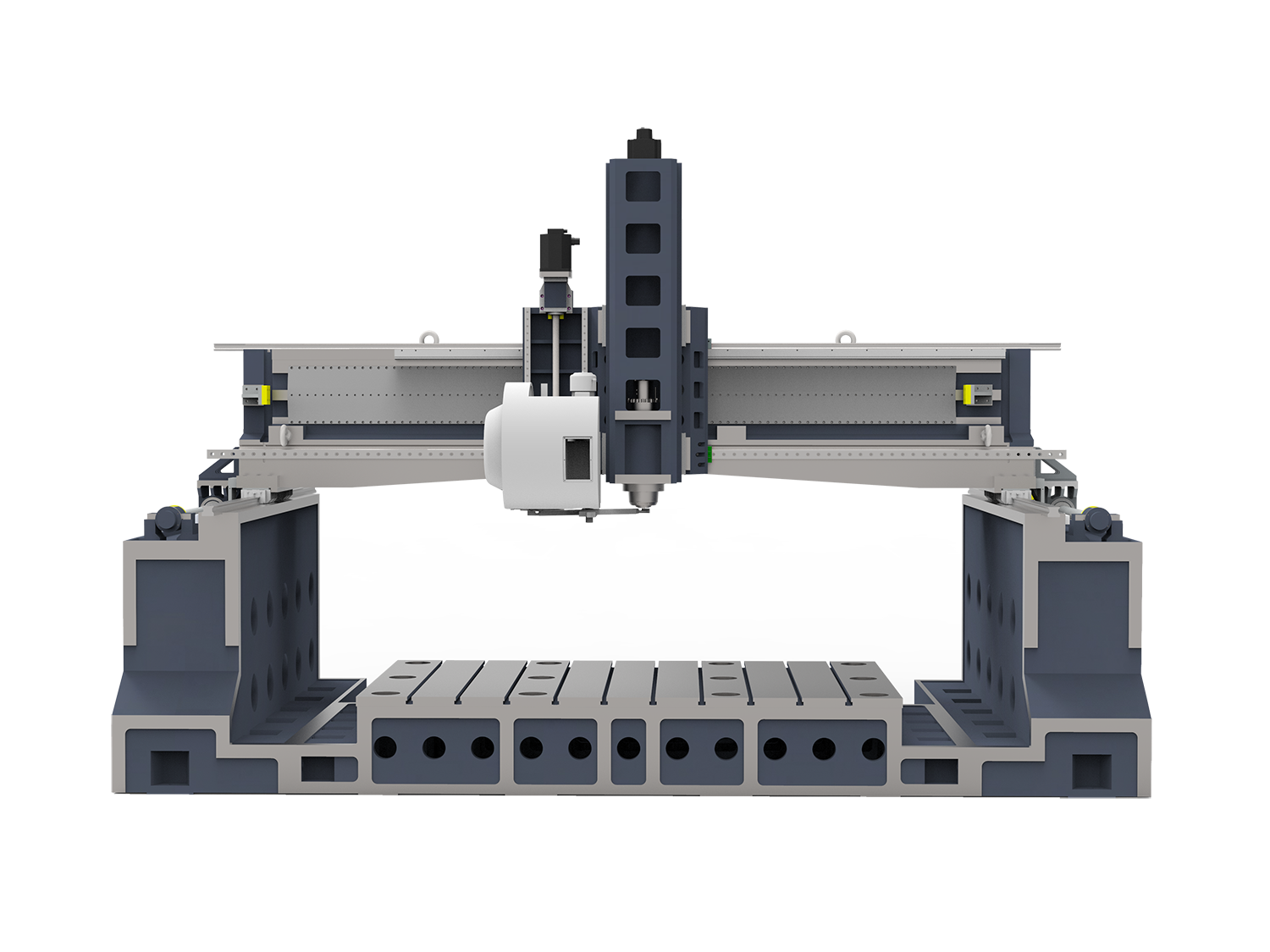

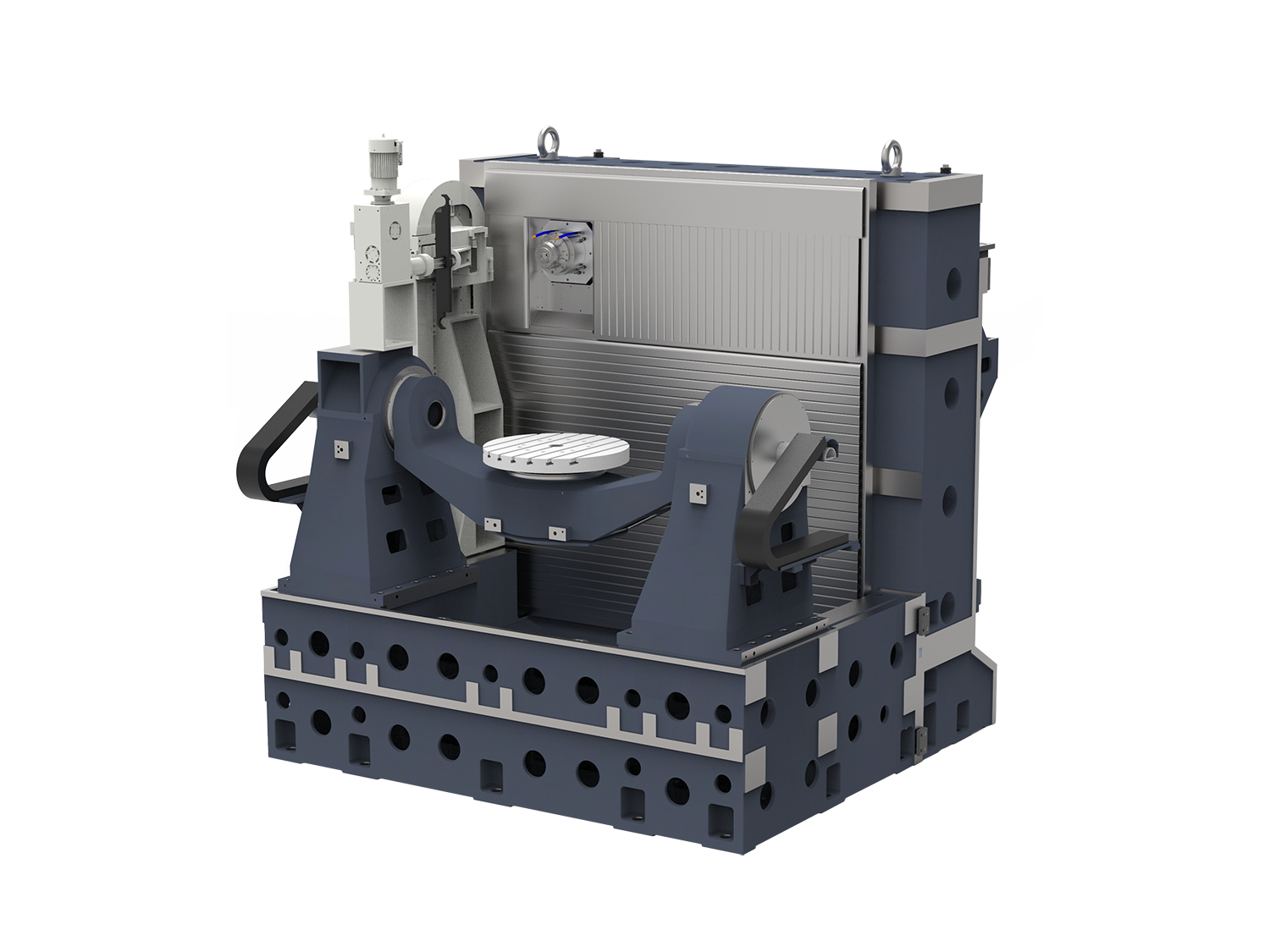

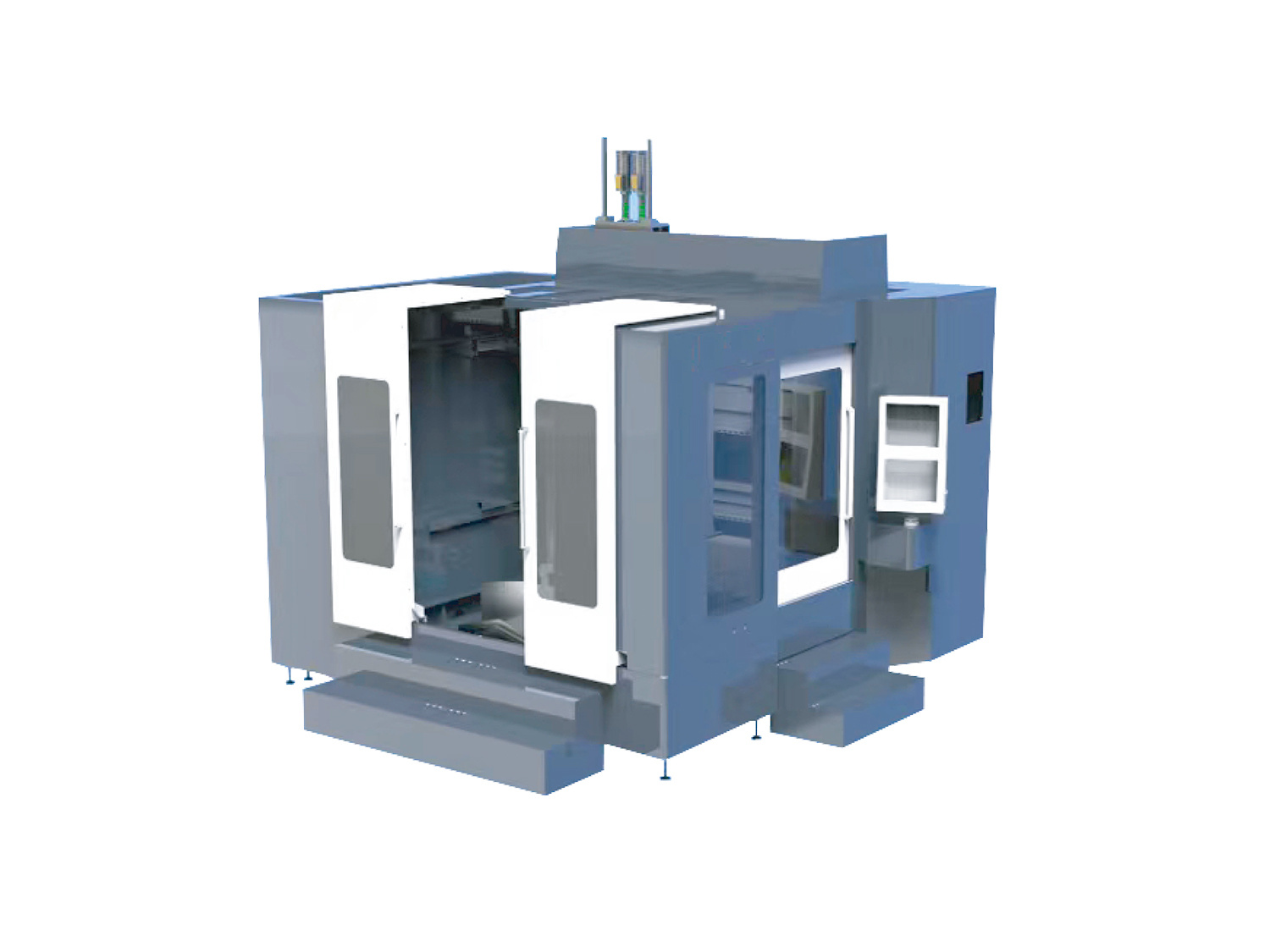

TF Gantry Cradle Series Machining Center

Key Words

Goldsmiths Smart, Equipment, Professional

Classification

New Energy Vehicle Series

Product Details

Solution

Control Arm Steering knuckle Valve body

Mechanical Characteristics

1. The machine tool adopts a gantry structure, with the base made from a mineral casting formula sourced from Switzerland, which has no internal stress and does not require aging to relieve stress, ensuring good static precision stability for the machine tool. Mineral castings have excellent shock absorption properties, allowing the material to absorb vibrations generated during processing, thus ensuring good dynamic performance of the machine tool. The thermal conductivity of the mineral casting material is one-fiftieth that of cast iron, ensuring long-term thermal stability of the machine tool.

2. Moving components are made of HT300 cast iron to ensure the rigidity of the machine tool.

3. Equipped with a DD direct drive five-axis cradle, the AC axis features a 3 arc second circular grating.

| Model | Unit | TF320 | TF400 | TF630 | TF800 |

| Stroke | |||||

| X-axis Stroke | mm | 400 | 500 | 850 | 1000 |

| Y-axis Stroke | mm | 600 | 800 | 800 | 1000 |

| Z-axis Stroke | mm | 350 | 350 | 550 | 650 |

| Distance from spindle nose to worktable (vertical) | mm | 100-450 | 150-500 | 100-650 | 100-750 |

| A-axis swing angle (minimum increment 0.001°) | ° | ±120° | -91~121° | -91~121° | ±120° |

| C-axis swing angle | ° | nx360° | nx360° | nx360° | nx360° |

| Worktable | |||||

| Worktable Area | mm | Φ320 | Φ400/14H7 | Φ630/18H7 | Φ800/18H7 |

| Worktable Load | mm | 100 | 200 | 850 | 1000 |

| Spindle | |||||

| Spindle Rated Power | kw | 7.5 | 20 | 30 | 30/54 |

| Spindle Speed | rpm | 36000 | 20000 | 24000 | 18000/10000 |

| Spindle Taper Hole | - | HSK E40 | HSK A63 | HSK A63 | HSK A63/HSK A100 |

| Spindle Output Torque (S1/S6) | N.m | 3.4/5.6 | 35/70 | 75/150 | 75/150, 260/300 |

| Feed | |||||

| Cutting Feed Rate | m/min | 20000 | |||

| Rapid Feed Rate | m/min | 36000 | |||

| Precision | |||||

| Positioning Accuracy | mm | 0.008/300 | |||

| Repeatability Accuracy | mm | 0.005/300 | |||

| Automatic Tool Change | |||||

| Tool Magazine Capacity | PCS | 20T/32T | 16T | 40T/60T | 40T/60T |

| Maximum Tool Diameter - Adjacent Tool | mm | Φ80 | Φ80 | Φ75 | Φ75 |

| Maximum Tool Diameter - Empty Adjacent Tool | mm | Φ140 | Φ140 | Φ140 | Φ140 |

| Maximum Tool Length | mm | 200 | 300 | 300 | 300 |

| Maximum Tool Weight | mm | 4 | 8 | 8 | 8/15 |

| Others | |||||

| Power Requirements | - | AC380, 50HZ, 30KVA | AC380, 50HZ, 50KVA | AC380, 50HZ, 90KVA | AC380, 50HZ, 90KVA |

| Air Source Pressure | Mpa | 0.5-0.7 | |||

| Net Weight of Machine | kg | Approximately 5000 | Approximately 6000 | Approximately 15000 | Approximately 20000 |

| Footprint | mm2 | 2625X1960 | 2230X4000 | 3640X4500 | 3000X5200 |

| Standard Accessories | Optional Accessories | ||

| SIEMENS 840D SL Controller | Tool Magazine (number of tool magazines according to technical agreement) | Guangzhou CNC | Transformer |

| Automatic Power Off Function | Electrical Box Air Conditioning | Spindle Center Water Output 20bar/60bar | Stabilizer |

| Spindle Taper Hole Cleaning Air Blow | Three-color Warning Light | Cutting Fluid Oil-Water Separation Device | |

| Spindle Cooling System | Work Light | Cutting Fluid Rain Mist Cooling Device | |

| Spindle Annular Cutting Fluid Cooling System | Operation Handwheel | Automatic Tool Measurement Device | |

| Centralized Automatic Lubrication Device | Foundation Level Adjustment Block | Automatic Workpiece Measurement Device | |

| Full Enclosure Protective Cover | Toolbox and Tools | Software for Special Workpiece Measurement Requirements | |

* Products are continuously updated, product parameters are subject to actual shipment.

Previous article

Next article

Previous article

Next article

Recommend products